Natural, earth-born slate is materially different from so-called synthetic slate options.

Natural slate is an extremely durable roofing material that can last for over a century with proper installation and maintenance. It’s resistant to fire, insects, and mildew, making it a great choice for both residential and commercial buildings.

The process for making roofing slate is labor intensive, but quite straight forward. First, explore and locate suitable deposits of slate rock. Geologists use various techniques to identify areas where slate is likely to be found, such as analyzing rock formations and studying aerial or satellite images. Once a suitable deposit of slate has been located, it is quarried using heavy machinery such as excavators and drills. Once excavated, the raw material is transferred to a processing plant for cutting, splitting and shaping. Roofing slate gets split into "books" using specialized tools, like fissuring hammers. The books are split into half, quarters, eights, on down until desired thickness. Then, the slate gets cut to size. Finally, it is sorted by size, thickness, and quality.

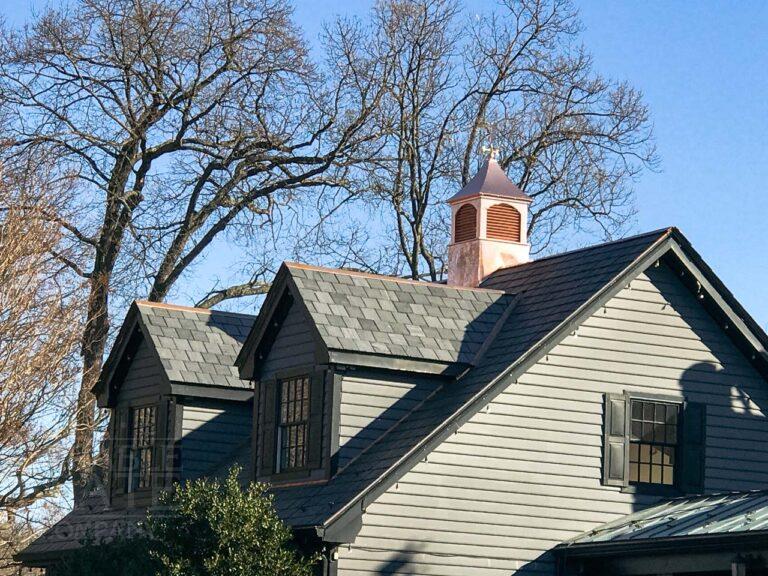

From beginning to end, roofing slate fabrication is a very labor-intensive process. But the result is hard to argue. The unique qualities of each slate piece, taken together, produce a roof unlike any other. Durable, lasting, and forever one-of-a-kind.

In contrast, artificial slate is not slate at all, rather just a play on words. It's made by molding a combination of materials, such as rubber or plastic, into something that kind-of resembles natural slate. Manufacturing synthetic slate involves a few steps: First, the raw materials are mixed together and poured into molds that simulate real slate. Although factories are best at making identical products quickly, natural slates are each unique. Artificial molds, then, add a bit of variation to the line to make the product look a bit more authentic. Once the rubber-plastic mixture has cooled and hardened, the piece is removed from the mold and inspected for defects. The survivors are cut to size and packaged up for shipping.

Synthetic slate can be made from various materials, such as PVC, TPO, EPDM and other thermoplastics. Some types of synthetic slate are created with a precise ratio of recycled materials, making them a tad more eco-friendly than unrecycled products. Overall, the better fake slates are made from higher quality materials and more time is taken to make them resemble actual slate. Artificial slate has the advantage of being lighter (so easier to ship and install) and less expensive to purchase and install. This makes sense; it’s plastic, not stone. And because it isn’t real stone, the trade-offs are plain:

Crucially,

synthetic slate is not as durable as natural slate. Real slate has centuries of evidence to prove beyond any doubt that it is robust material for roofing. Fake slate is a relatively new product and simply hasn’t established itself as a no-compromise alternative. Despite the manufacturer’s claim, fake slate is more likely to show serious wear much, much sooner than the real thing. This includes discoloration and various deformities, like curling and cracking. And although they make the effort, there’s no practical way to make every synthetic slate tile as unique as real slate. On a roof, this limited variation blends together into something bland and uniform looking. A bit like asphalt shingles, they lose their character and chunky quality and end up looking manufactured and uninteresting.